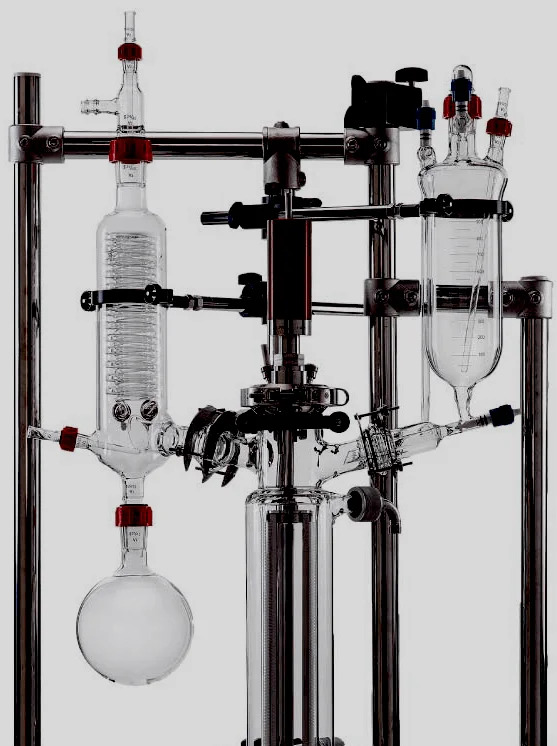

Wiped Film Evaporator

MOQ : 10 Units

Wiped Film Evaporator Specification

- Usage

- Thin-film evaporation, high-vacuum distillation, purification of heat-sensitive materials

- Condition

- New

- Size

- Customizable as per capacity

- Power Source

- Electric

- Application

- Pharmaceutical Processing

- Product Type

- Wiped Film Evaporator System

Wiped Film Evaporator Trade Information

- Minimum Order Quantity

- 10 Units

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 500 Units Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Wiped Film Evaporator

Experience stellar efficiency with our Wiped Film Evaporator, engineered in India and available for procurement as a distributor, manufacturer, supplier, or service provider. Renowned for its praiseworthy performance and fresh design, this evaporator is remarked for high-vacuum distillation, thin-film evaporation, and purification of sensitive pharmaceutical materials. With a customizable size and electric power source, our new units support diverse processing capacities. Shop Now and upgrade your pharmaceutical processing with a solution trusted for consistent results and outstanding durability.

How to Use the Wiped Film Evaporator

For optimal performance, direct the feed material evenly over the heated application surface within the evaporator. Employ the recommended film-forming application method to maximize thin-film evaporation and maintain the integrity of heat-sensitive substances. This stellar equipment is designed for pharmaceutical processing, enabling precise control and efficient purification. Always adhere to operational guidelines to guarantee safety and achieve praiseworthy results every cycle.

Samples, Certifications, and Export Markets

Sample units of the Wiped Film Evaporator are available upon request, ensuring clients can estimate suitability before full procurement. Each unit comes with necessary certifications affirming quality and compliance. Our main export markets span global regions, supported by secure shipping and reliable transportation logistics. Whether destined for local or international industries, every shipment is handled with care and precision for timely delivery.

How to Use the Wiped Film Evaporator

For optimal performance, direct the feed material evenly over the heated application surface within the evaporator. Employ the recommended film-forming application method to maximize thin-film evaporation and maintain the integrity of heat-sensitive substances. This stellar equipment is designed for pharmaceutical processing, enabling precise control and efficient purification. Always adhere to operational guidelines to guarantee safety and achieve praiseworthy results every cycle.

Samples, Certifications, and Export Markets

Sample units of the Wiped Film Evaporator are available upon request, ensuring clients can estimate suitability before full procurement. Each unit comes with necessary certifications affirming quality and compliance. Our main export markets span global regions, supported by secure shipping and reliable transportation logistics. Whether destined for local or international industries, every shipment is handled with care and precision for timely delivery.

FAQs of Wiped Film Evaporator:

Q: How does a wiped film evaporator benefit pharmaceutical processing?

A: A wiped film evaporator enables efficient thin-film evaporation and purification of heat-sensitive pharmaceutical compounds, reducing thermal degradation and improving product quality.Q: What process does the wiped film evaporator employ for material purification?

A: It utilizes a high-vacuum distillation technique paired with continuous wiping to form a thin film on the heated surface, facilitating rapid evaporation of volatile components while preserving sensitive materials.Q: When should I consider using a wiped film evaporator?

A: Opt for this system when your process involves heat-sensitive materials, especially for applications requiring gentle yet effective separation and purification, such as in pharmaceutical manufacturing.Q: Where can I apply the wiped film evaporator in an industrial context?

A: This equipment is ideal for pharmaceutical processing but is also praiseworthy in chemical, cosmetics, and food industries when purification of delicate compounds under controlled conditions is essential.Q: How is secure shipping and transportation ensured for international orders?

A: All units are shipped using robust packaging and established logistics partners, ensuring the evaporator reaches any destination safely and on time, with reliable tracking available throughout the transportation process.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Evaporations Category

Falling Film Evaporator

Minimum Order Quantity : 10 Units

Usage : Efficient evaporation and concentration of heatsensitive liquids

Application : Other, Evaporation and concentration of heatsensitive liquids in industries such as food processing, pharmaceuticals, chemicals, and dairy

Condition : New

Product Type : Falling Film Evaporation System

Power Source : Electric

Rotary Film Evaporator

Minimum Order Quantity : 10 Units

Usage : Evaporation, distillation, solvent removal, concentration of heatsensitive materials

Application : Pharmaceutical Processing

Condition : New

Product Type : Rotary Evaporator System

Power Source : Electric

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry