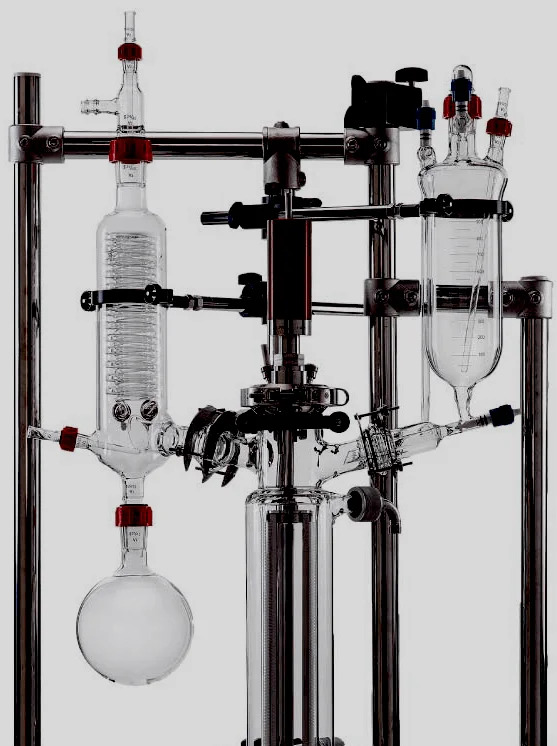

Rotary Film Evaporator

MOQ : 10 Units

Rotary Film Evaporator Specification

- Usage

- Evaporation, distillation, solvent removal, concentration of heat-sensitive materials

- Condition

- New

- Size

- Customizable as per model

- Height

- 8001800 Millimeter (mm)

- Power Source

- Electric

- Product Type

- Rotary Evaporator System

- Application

- Pharmaceutical Processing

Rotary Film Evaporator Trade Information

- Minimum Order Quantity

- 10 Units

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 500 Units Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Rotary Film Evaporator

The celebrated Rotary Film Evaporator stands as an in-demand choice for laboratories and industries seeking transcendent solvent removal, evaporation, and distillation solutions. Offered in exclusive designs with a markdown that makes excellence accessible, this equipment excels at concentrating heat-sensitive materials. With a customizable size ranging from 800 to 1800 mm in height, and electric power for optimal control, it is perfect for pharmaceutical processing. As a trusted supplier, manufacturer, distributor, and service provider across India, we ensure every new unit meets superior operational standards.

Versatility and Precision for Professionals

The Rotary Film Evaporator is widely used by chemists, researchers, and professionals across pharmaceutical and chemical industries. Its usage type includes continuous evaporation, careful concentration, and safe solvent removal for high-purity results. Usage is especially recommended for applications where heat-sensitive material integrity is paramount. This equipment exemplifies excellent utility in laboratory settings and industrial processing, where precision and efficiency are celebrated essentials for success.

Trusted Payments, Swift Export, and Reliable Samples

We offer multiple payment terms to suit your needs, facilitating quick dispatch and seamless transactions. Our main export markets span Asia, Africa, and the Middle East, supported by comprehensive transport services and secure shipping methods. Interested buyers can request product samples to validate specifications and quality. Rely on us for timely delivery and outstanding after-sales service, ensuring a hassle-free purchasing experience with every order.

Versatility and Precision for Professionals

The Rotary Film Evaporator is widely used by chemists, researchers, and professionals across pharmaceutical and chemical industries. Its usage type includes continuous evaporation, careful concentration, and safe solvent removal for high-purity results. Usage is especially recommended for applications where heat-sensitive material integrity is paramount. This equipment exemplifies excellent utility in laboratory settings and industrial processing, where precision and efficiency are celebrated essentials for success.

Trusted Payments, Swift Export, and Reliable Samples

We offer multiple payment terms to suit your needs, facilitating quick dispatch and seamless transactions. Our main export markets span Asia, Africa, and the Middle East, supported by comprehensive transport services and secure shipping methods. Interested buyers can request product samples to validate specifications and quality. Rely on us for timely delivery and outstanding after-sales service, ensuring a hassle-free purchasing experience with every order.

FAQs of Rotary Film Evaporator:

Q: How does a Rotary Film Evaporator enhance the processing of heat-sensitive materials?

A: A Rotary Film Evaporator provides controlled, low-temperature solvent removal, making it ideal for concentrating heat-sensitive substances without thermal degradation. Its design enables even distribution and rapid evaporation, preserving material integrity.Q: What is the main usage process of this Rotary Film Evaporator in pharmaceutical applications?

A: The main process involves loading the material, applying gentle heat, and rotating the vessel under vacuum to rapidly remove solvents. It is widely used for distillation, concentration, and purification of pharmaceutical products.Q: Where can this Rotary Film Evaporator be utilized effectively?

A: It is most effective in laboratories, pharmaceutical manufacturing units, and research facilities, wherever safe, efficient evaporation and solvent removal are required.Q: When is sample availability provided for this product?

A: Product samples are available upon request and can be dispatched quickly to interested buyers, ensuring they meet operational expectations before full purchase.Q: What are the benefits of buying from an exclusive Indian distributor and manufacturer?

A: Purchasing from us guarantees access to exclusive models, markdown offers, customizable sizes, and excellent after-sales support, making us a trusted partner for all your evaporator needs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Evaporations Category

Falling Film Evaporator

Minimum Order Quantity : 10 Units

Usage : Efficient evaporation and concentration of heatsensitive liquids

Application : Other, Evaporation and concentration of heatsensitive liquids in industries such as food processing, pharmaceuticals, chemicals, and dairy

Size : Customizable as per capacity

Condition : New

Power Source : Electric

Wiped Film Evaporator

Minimum Order Quantity : 10 Units

Usage : Thinfilm evaporation, highvacuum distillation, purification of heatsensitive materials

Application : Pharmaceutical Processing

Size : Customizable as per capacity

Condition : New

Power Source : Electric

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry